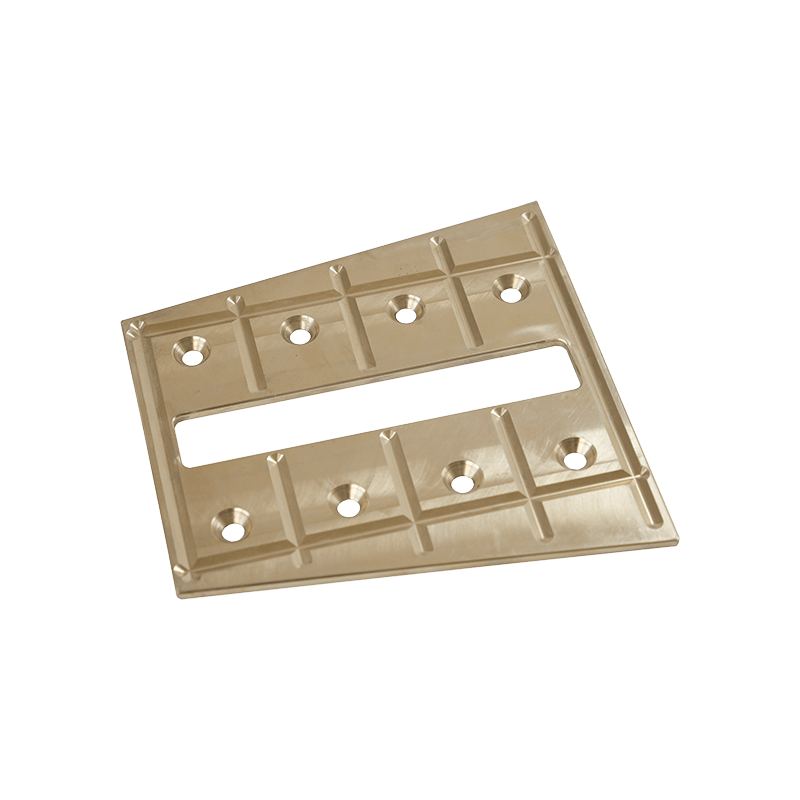

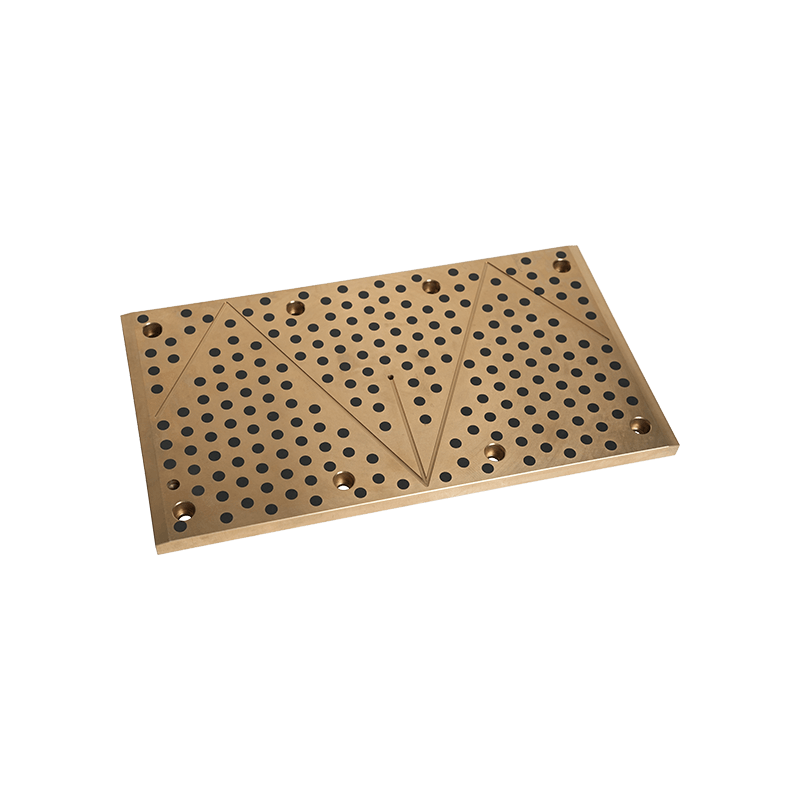

Self-lubricating scraper bearings have become increasingly significant in various industries, not only for their performance but also for their positive environmental impact. Their adaptability and diversity contribute to sustainability efforts in several key ways.

Self-lubricating scraper bearings are designed to function effectively across a broad range of temperatures, pressures, and environmental conditions. This adaptability allows them to be used in challenging environments, such as chemical processing plants, food and beverage manufacturing, and outdoor applications, without the need for frequent maintenance or lubrication.

By performing reliably in diverse conditions, these bearings minimize equipment failures and downtime. This reliability decreases the frequency of replacements and repairs, reducing material waste and the environmental impact associated with manufacturing and disposing of new parts.

Many self-lubricating materials exhibit excellent chemical resistance, allowing them to operate in corrosive environments. This reduces the need for additional protective coatings or lubrication systems, which can be environmentally harmful.

Self-lubricating scraper bearings find applications in numerous industries, including automotive, aerospace, mining, and manufacturing. Their versatility allows them to replace traditional bearings in applications where lubrication is challenging or undesirable, contributing to more sustainable operations.

Many manufacturers offer customizable self-lubricating bearings to meet specific application needs. This diversity means that industries can select bearings tailored to their operational requirements, enhancing efficiency and reducing resource waste.

By incorporating self-lubricating bearings, machinery can achieve higher energy efficiency. These bearings reduce friction and energy consumption, leading to lower carbon footprints in manufacturing processes and operations.

Recyclable Materials: Self-lubricating scraper bearings are often made from materials that can be recycled at the end of their life cycle. This aspect contributes to a circular economy, minimizing waste and promoting resource conservation.

As environmental awareness grows, many manufacturers are developing self-lubricating bearings using eco-friendly materials. These options reduce the reliance on harmful substances, aligning with modern sustainability goals.

Cost-Effectiveness: Although self-lubricating bearings may have a higher initial cost, their longevity and reduced maintenance requirements result in lower total ownership costs. This economic benefit encourages industries to adopt sustainable practices while maintaining profitability.

As businesses increasingly focus on sustainability and reducing their environmental impact, using self-lubricating bearings aligns with corporate social responsibility goals. This alignment can improve brand reputation and market competitiveness.

The environmental impact of self-lubricating scraper bearings is significantly influenced by their adaptability and diversity. Their ability to perform in a wide range of conditions and applications reduces the need for additional lubricants, maintenance, and replacements, thereby minimizing waste. Furthermore, the use of recyclable and eco-friendly materials enhances their sustainability profile. By integrating self-lubricating scraper bearings into their operations, industries can not only improve efficiency but also contribute positively to environmental conservation efforts.

English

English Deutsch

Deutsch Español

Español русский

русский

+0086-513-88690066

+0086-513-88690066