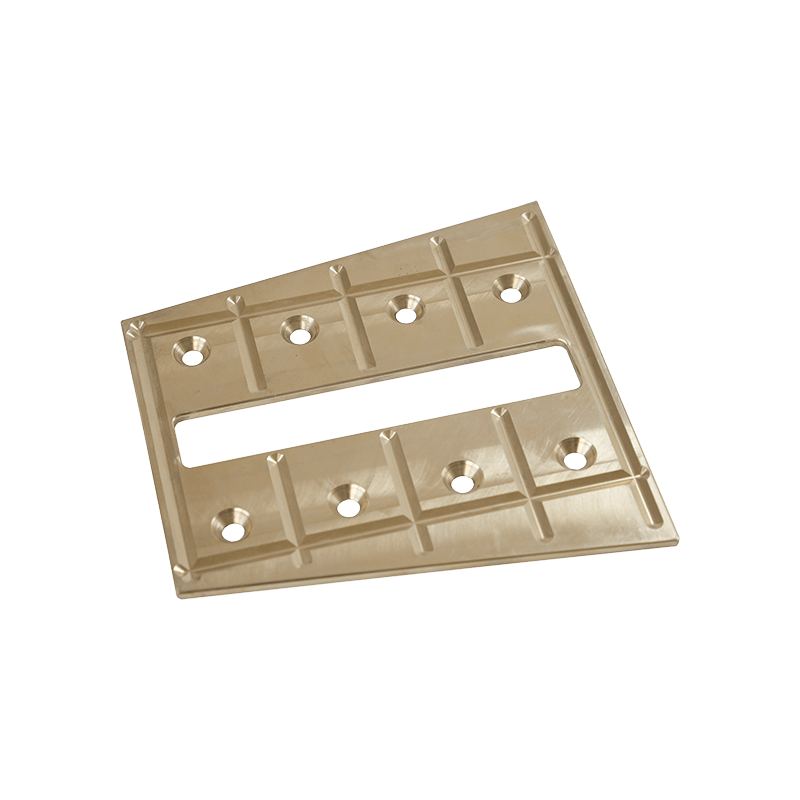

Whether the steel-copper composite bearing plate can meet the application of extreme working conditions such as high temperature and high load depends mainly on the specific requirements of its material combination, production process, design and application environment. The combination of steel-copper composite materials gives this type of bearing plate some unique advantages, enabling it to perform well in certain high temperature and high load conditions. However, specific analysis is also required for different working conditions.

Under high temperature conditions, the thermal stability and high temperature resistance of bearing materials are crucial. The performance of steel-copper composite bearing plates is affected by the following factors:

Copper has excellent thermal conductivity, so copper-based materials can help dissipate heat, allowing bearing plates to better cope with the problem of heat accumulation in high temperature environments. Especially in the case of high-speed operation and friction generating more heat, the thermal conductivity of copper helps to quickly conduct heat away, thereby avoiding overheating of the bearing.

Copper has a low melting point (about 1083°C), and in extremely high temperature environments, there may be a risk of material softening and deformation. However, the melting point of steel materials is high (about 1370°C), so the high temperature resistance of steel-copper composite materials is enhanced to a certain extent by the steel matrix. Overall, the steel-copper composite bearing plate is suitable for general high-temperature working conditions, but when it exceeds the melting point of copper, performance degradation may occur, and special attention should be paid to temperature control.

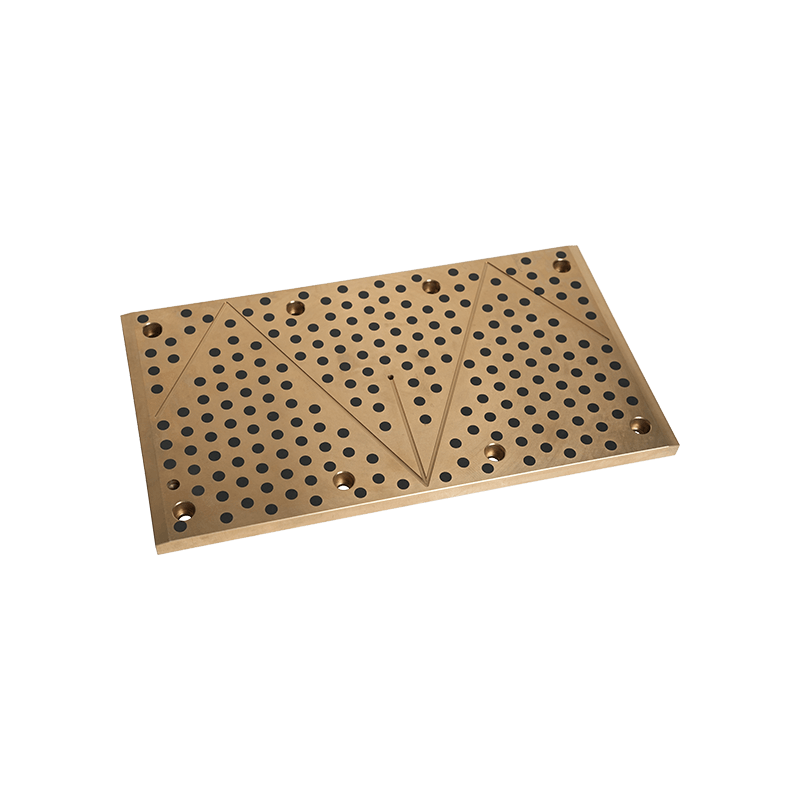

In high-temperature environments, the heat generated by friction may cause the lubrication performance of traditional materials to deteriorate, and even cause problems such as ablation and adhesion. Copper has good self-lubricating properties, which makes the steel-copper composite bearing plate show good anti-friction performance under certain high-temperature and high-load conditions. However, when the temperature is too high, additional lubrication measures may be required to avoid excessive wear.

The high-load bearing capacity of the steel-copper composite bearing plate mainly depends on the following aspects:

The steel-based material provides the strength and hardness of the composite bearing plate, enabling it to withstand high external loads. The compressive strength and hardness of steel can usually meet the needs under heavy load conditions, especially in the fields of mining machinery, metallurgical equipment, etc., where steel-copper composite materials are often used in applications where heavy objects are pressed.

Although copper has low strength, it has good elasticity and wear resistance, which can effectively reduce wear caused by friction. Under high-load conditions, the self-lubricating properties of copper help reduce the friction coefficient, thereby avoiding excessive heat accumulation and wear.

The composite structure of the steel-copper composite bearing plate complements the overall performance of the material. The steel layer provides high-strength support, while the copper layer improves wear resistance and lubrication performance. Such a composite structure enables the bearing plate to maintain good load-bearing capacity and durability under high load.

Under high-load conditions, the bearing plate usually generates a lot of heat, resulting in thermal expansion. Copper has a larger thermal expansion coefficient than steel, so the material may change in size under long-term high-load operation. To address this problem, the design of the steel-copper composite bearing plate usually takes into account the expansion characteristics of the material to avoid deformation or damage caused by uneven thermal expansion.

Under extreme conditions of high temperature and high load, the performance of the steel-copper composite bearing plate usually depends on the synergy of the two. Under such extreme conditions, steel-copper composite materials can provide better load-bearing capacity and friction performance, but additional measures are also required, such as optimization of the lubrication system or control of ambient temperature, to avoid material degradation.

Steel-copper composite bearing plates are often used in high-load and high-temperature environments such as metallurgy, mining machinery, wind power generation, and offshore drilling platforms. Under these conditions, the bearing plate not only needs to withstand heavy pressure, but also needs to operate for a long time at high temperature. Therefore, choosing a suitable steel-copper composite bearing plate and combining it with a suitable lubrication method can greatly improve its service life and stability under these extreme working conditions.

In order to enable the steel-copper composite bearing plate to better cope with extreme working conditions such as high temperature and high load, manufacturers usually optimize the following aspects:

By optimizing the thickness ratio of the copper layer and the steel base layer, the bearing capacity and high temperature resistance of the bearing plate can be improved. For example, a thinner copper layer can better reduce weight while enhancing heat conduction; while a thicker steel layer provides stronger support.

Through surface coating, heat treatment and other methods, the high temperature resistance, wear resistance, and corrosion resistance of the steel-copper composite bearing plate can be further improved. For example, the use of high temperature protective coating can further improve the stability of the material under extreme working conditions.

In order to reduce the negative impact of high temperature environment on the steel-copper composite bearing plate, it is usually necessary to cooperate with a suitable lubrication and cooling system. Regular lubrication and cooling can not only increase the service life of the bearing plate, but also reduce the heat accumulation problem caused by friction.

The steel-copper composite bearing plate can show excellent performance under extreme working conditions such as high temperature and high load, but its application still has certain limitations. Its high strength, good friction performance and thermal conductivity make it suitable for most high temperature and high load environments, but for ultra-high temperature or ultra-heavy load conditions, additional optimization design and auxiliary measures are still needed. Through fine design and appropriate process optimization, steel-copper composite bearing plates can achieve better performance under these extreme conditions and meet engineering requirements.

English

English Deutsch

Deutsch Español

Español русский

русский

+0086-513-88690066

+0086-513-88690066